Raj group is one of the leading market players in the GCC region for more than Eighteen years producing around six million tons per annum of high quality gabbro aggregates and quarry products. Having started in 2005, the company has in very short period expanded and captured a large share of UAE and Qatar market by providing quality and reliability of supply.

- A pool of talented, well-qualified technical manpower & skilled workers for day-to-day monitoring and operation to ensure consistent production of high quality aggregates at our state-of-the art crushing plant.

- A Well-equipped laboratory with expert technicians to carry out physical analysis of aggregates on a periodical basis. Also, pre and post blasting tests on rocks are being undertaken regularly to strictly adhere to the quality standards.

- Our own stockyard at Fujairah Shipyard with a facility and capability to load aggregate materials either through conveyor jetty or grab jetty.

- Our own dedicated logistics division. Besides, we have tied-up with some of the leading transporters to deliver our product range at length and breadth of U.A.E

- A large client base from all over U.A.E including Construction & Civil Contracting Industries, RMC & Concrete Block Manufacturers, and Asphalt Manufacturers etc. The prominent client includes Dutco, Bin Laden, ERC, Yuksel, Nael Bin Harmal, Athena, China Harbour, Bin Hafeez, Khansaheb, ASCON, SGCC, NCTC, Darwish, Orimix, Gulf ReadyMix, Ghantoot, Tremix, Sijimix, Archirodon, Al Nuaimi, etc.

- We also cater to the requirement of aggregates in export markets viz.Qatar, Kuwait and Bahrain.

PLANT (Primary)

PLANT (Secondary)

Our quarries have one of its kind four-stage state of art crushing plant (Make: Sandvik, Sewden). Our highly automated plants with PLC Controls is capable of producing up to 1000 MTPH. Four stage crushing, consisting of Primary-Jaw JM1511 assisted by FF1220H linear scalping screen, of Primary-Jaw JM1511 assisted by FF1220H linear scalping screen. Secondary-Cone H6800, Tertiary-Cone H4800M & Cone H4800F, Quaternary-Merlin VSI (RP 109), ensures high quality production as per ASTM and BS specifications.

MINING / QUARRIES

Mining operations are supervised by a vastly experienced mining engineer. Numerous drilling machines, excavators, dozers, dumpers work regularly to ensure availability of high quality raw material at all times by blending during loading based on drill hole sample reports from all blast patterns. Multi level Bench preparation helps in catering to different requirements of our varies customers.

VSI (RP 109), ensures high quality production as per ASTM and BS specifications. VSI (RP 109), ensures high quality production as per ASTM and BS specifications. VSI (RP 109), ensures high quality production as per ASTM and BS specifications.

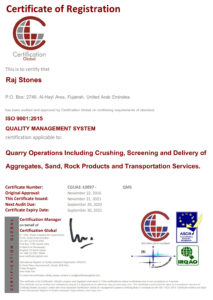

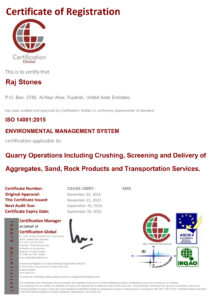

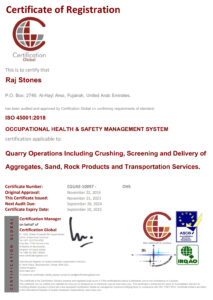

QUALITY CONTROL

Quality is standard at our quarries. To maintain and enhance quality of our products, we have implemented an in-house quality system. A well equipped laboratory managed by expert technicians helps constantly to monitor quality. Physical analysis of aggregates is done on a day to day basis. Pre & post blasting tests on rocks is conducted to ensure consistency in specific gravity. Our seriousness to quality can be gauged by the fact that quarterly third party tests are also conducted. Quality control is carried out by highly qualified personnel is accordance with the ISO-9001: 2015, QMS, ISO-14001: 2015 EMS, ISO- 45001: 2018 OHS. ATTAIN